|

|

| Esmeriladoras Cilíndricas Hidráulicas - serie UCG | Esmeriladoras Cilíndricas Hidráulicas - serie HUCG | Rectificadora Cilíndrica sin Centros / Amoladora sin Puntas |

|

- Machine Bed: Made of close

grained Cast Iron, well ribbed. |

|

|

Specifications: |

| Model | UCG-200 | UCG-254L | UCG-254H |

| Max. diameter of swing (mm) | 200 | 254 | 254 |

| Max. distance between centres (mm) | 450 / 600 | 500 / 625 / 750 | 1000 / 1250 / 1500 |

| Height of centre (mm) | 100 | 127 | 127 |

| Table speed infinitely variable min. / max. (mm/min) | 400 / 5000 | 400 / 5000 | 400 / 4000 |

| Wheelhead and wheel feed | |||

| Grinding wheel (OD x Width x Bore) (mm) | 300x25x75 | 350x40x127 | 350x40x127 |

| Automatic cross feed of wheel at each left hand reversal of table (travel in two steps) (mm) | 0.01 / 0.02 | 0.01 / 0.02 | 0.01 / 0.02 |

| Speed of wheel spindle (rpm) | 1750 | 1600 - 2090 | 1600 - 2090 |

| Workhead | |||

| Speed of workhead (rpm) | 80 - 150 - 270 | 60 - 120 - 212 - 380 | 60 - 120 - 212 - 380 |

| Morse taper in workhead spindle | MT-3 | MT-4 | MT-4 |

| Swivel of workhead | 90 degrees | 90 degrees | 90 degrees |

| Morse taper in tailstock | MT-2 | MT-3 | MT-3 |

| Internal Grinding | |||

| Spindle diameter (mm) | 60 | 60 | 60 |

| Max quill length (rpm) | 70 | 70 | 70 |

| Max. quill diameter (mm): | 18 | 18 | 18 |

| Min. / Max. diameter of hole grinding (mm): | 16 / 60 | 16 / 60 | 16 / 60 |

| Min. / Max. diameter of grinding wheel (mm): | 15 / 40 | 15 / 40 | 15 / 40 |

| Spindle quill speed (rpm): | 18000 | 18000 | 18000 |

| Electric Motors (HP) | |||

| Wheelhead motor | 2.0 | 5.0 | 5.0 |

| Workhead motor | 0.5 | 1.0 | 1.0 |

| Internal Grinding Attachment motor | 1.0 | 1.0 | 1.0 |

| Hydraulic Pump motor | 1.0 | 1.0 | 1.0 |

| Coolant Pump motor | 0.15 | 0.15 | 0.15 |

|

|

|

Other Specifications: |

| Model | Max. Swivel of Table (degrees) | Nett Weight | Dimensions |

| UCG-200 / 450 | -2 to +7 | 1250 | 2.0 x 1.4 x 1.6 |

| UCG-200 / 600 | -2 to +6 | 1500 | 2.0 x 1.4 x 1.6 |

| UCG-254L / 500 | -2 to +7 | 2000 | 2.0 x 1.4 x 1.6 |

| UCG-254L / 625 | -2 to +6 | 2250 | 2.0 x 1.4 x 1.6 |

| UCG-254L / 750 | -2 to +6 | 2500 | 2.6 x 1.4 x 1.7 |

| UCG-254H / 1000 | -2 to +6 | 3000 | 3.1 x 1.4 x 1.7 |

| UCG-254H / 1250 | -2 to +5 | 3100 | 3.2 x 1.4 x 1.7 |

| UCG-254H / 1500 | -2 to +5 | 3225 | 3.6 x 1.4 x 1.7 |

|

Standard

Accessories: Common with all models: Motors with starter and belts, coolant pump with tank, grinding wheel, diamond dresser, set of service tools with UCG-200 series models: Plain dead centre MT-2 (Threaded), plain dead centre MT-3 with UCG-254 series models: Plain dead centre MT-3 (Threaded), plain dead centre MT-4 |

|

Optional

Accessories: Common with all models: Internal Grinding Attachment, wheel balancing arbour, wheel balancing stand, wheel angle dressing attachment, additional wheel flange, two-point steady rest, three-point steady rest, true chuck flange with UCG-200 series models: True chuck 110 mm, revolving centre MT-2, carbide dead centre MT-2, carbide dead centre MT-3 with UCG-254 series models: True chuck 135 mm, revolving centre MT-3, carbide dead centre MT-3, carbide dead centre MT-4, hydraulic tailstock |

| -

Machine Bed: Made of high grade Cast Iron. Ribbed Box structure design,

high quality stress relieved castings. Three point setup. - Workhead & Wheelhead: Running on hydro-dynamic multi-point bearings. Cartridge Type. The wheel slide can be swiveled through +/- 45 degrees. - Infeed System: Infeed is operated by precision ground cam. The movement of infeed slide (wheel slide) is based on hardened, ground and preloaded roller guideways, which guarantee stick-slip free movement and fine repetitive accuracy of +/- 1 micron. Plunge grinding at any desired approach angle up to 45 degrees can be done. Single lever operates the complete grinding cycle. According to the work piece requirement, the following grinding cycles can be selected: 1. Plunge; 2. Traverse with Infeed on L.H.S.; 3. Traverse with Infeed on R.H.S.; 4. Traverse with Infeed on L.H.S. and R.H.S. - Automatic Grinding Cycle: It has a Rapid approach - Coarse Feed - Fine Feed - Sparkout and Rapid retraction of the wheelhead and the infeed handwheel to the preselected position. The cycle also controls Start / Stop of the workhead motor, coolant motor and table reciprocation. In case of a long job, the termination of the grinding cycle is selectable either at Left, Right or at any position of the reciprocating table. While internal grinding cycle is running, wheel slide always remains in retracted position. The Infeed and Fine feed as well as the feed rate of Coarse and Fine feed are selectable. There is an optional arrangement to equip the cycle with an in-process gauging device for direct measurement during grinding. - Tailstock: Its upper part moves on hardened, ground and preloaded roller guideways. Facilities such as Fine taper setting of +/- 20 microns and hydraulic tailstock actuation are optionally provided - Hydraulic / Electrical System: The hydraulic powerpack is equipped with solenoid valve, hydraulic pump, motor, etc., which is located outside the machine to avoid vibration & thermal distortion. The electric controls cabinet is also housed outside the machine for easy maintenance. - Swivel Table: Table is arranged to swivel for taper grinding. Graduations at the right-hand end indicate taper on diameter per millimeters and the included angle in degrees. The graduated scale permits initial setting and a dial indicator can be attached to enable fine corrections to be applied by screw adjustment. - Internal Grinding Attachment: The hinged type Internal Grinding Attachment with its independent motor is conveniently located on the wheelhead. It has a fast grinding action and can be quickly swung into a grinding position. The work piece can be externally and internally ground in one setting. Taper hole can be ground either by swiveling the workhead or the table. During the internal grinding operation, safety interlocking system provided avoids sudden retraction of wheelhead. The internal grinding spindles are run on precision fiber cage bearings. A wide selection of spindles is available depending on the requirement of the work piece. |

|

|

| Specifications: |

| Model | HUCG-260 | HUCG-350 |

| Max. diameter of swing (mm) | 260 | 350 |

| Max. distance between centres (mm) | 500 / 800 / 1000 / 1200 | 500 / 800 / 1000 / 1200 |

| Height of centre (mm) | 130 | 175 |

| Table speed infinitely variable min. / max. (mm/min) | 100 / 5000 | 100 / 5000 |

| Wheelhead and wheel feed | ||

| Grinding wheel (OD x Width x Bore) (mm) | 400x50x127 | 400x50x127 |

| Speed of wheel spindle (rpm) | 1500 / 1740 / 2020 / 2350 | 1500 / 1740 / 2020 / 2350 |

| Workhead | ||

| Speed of workhead (rpm) | 56 to 630 (in 8 steps) | 56 to 630 (in 8 steps) |

| Morse taper in workhead spindle | MT-5 | MT-5 |

| Morse taper in tailstock | MT-3 | MT-3 |

| Infeed System | ||

| Rapid approach (mm) | 40 | 40 |

| Infeed with handwheel (mm) | 20 | 20 |

| Min. incremental on diameter (mm) | 0.001 | 0.001 |

| Swivel range | +/- 45 degrees | +/- 45 degrees |

| Max. plunge depth on diameter (mm) | 1.7 | 1.7 |

| Coarse infeed range on dia. (mm/min) | 0.015 - 6 | 0.015 - 6 |

| Fine infeed range on dia. (mm/min) | 0.015 - 3 | 0.015 - 3 |

| Spark Off time (sec.) | 0 - 60 | 0 - 60 |

| Internal Grinding | ||

| Spindle diameter (mm) | 60 | 60 |

| Spindle speed (rpm) | 18000 | 18000 |

| Accuracy - Roundness on Live Spindle | ||

| with standard equipment | 0.002 | 0.002 |

| with special optional equipment | 0.001 / 0.0005 | 0.001 / 0.0005 |

| Electric Motors (HP) | ||

| Wheelhead motor | 5.0 | 5.0 |

| Workhead motor | 0.37 | 0.37 |

| Internal Grinding Attachment motor | 1.0 | 1.0 |

| Hydraulic Pump motor | 2.0 | 2.0 |

| Coolant Pump motor | 0.15 | 0.15 |

|

|

|

Other Specifications: |

| Model | Max. Swivel of Table (degrees) | Nett Weight |

| HUCG-260 / 500 & HUCG-350 / 500 | -3 to +12 | 2800 |

| HUCG-260 / 800 & HUCG-350 / 800 | -3 to +9 | 3500 |

| HUCG-260 / 1000 & HUCG-350 / 1000 | -2 to +8 | 3900 |

| HUCG-260 / 1200 & HUCG-350 / 1200 | -1 to +7 | 4200 |

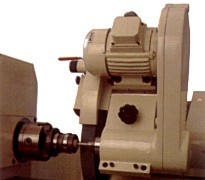

Internal Grinding Attachment |

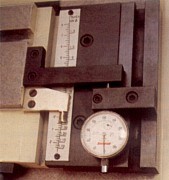

Swivel Table |

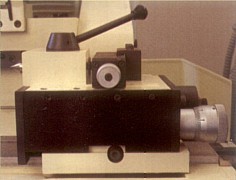

Tailstock |

| Standard Accessories: Common with all models: Motors with starter and belts, coolant pump with tank, grinding wheel, diamond dresser, set of service tools, Carbide dead centre MT-5, carbide dead centre MT-3, table mounted swivel dresser, wheel dressing attachment in tailstock, wheel balancing mandrel, live spindle drawbar with adaptor, two wheel adaptors for internal grinding spindle |

| Optional Accessories: Wheel balancing arbour, wheel balancing stand, two-point steady rest, three-point steady rest, precision 3-jaw chuck with adaptor and flange, precision 4-jaw chuck with adaptor and flange, wheel angle dressing attachment, radius dressing attachment, hydraulic side dressing attachment, machine lamp, magnetic filter with standard coolant tank, paper cum magnetic filter with special coolant tank, in-process gauging equipment, variable speed for workhead, variable speed for wheelhead |

| -

Straight parts, parts with shoulders, tapered parts, parts of various

shapes, etc. can be ground easily by using suitable grinding wheels - Machine can grind steel, hardened and unhardened brass, copper, aluminium, etc. - BED: The bed of the machine is box-shaped seasoned casting. - GRINDING WHEELHEAD: The grinding wheel spindle is made of hardened and ground alloy steel, it runs on anti-friction white metal adjustable type bush bearings. The axial thrust is taken up by two direction axial thrust collar which is hardened and ground. Bearings are automatically lubricated by means of a splash system - REGULATING WHEELHEAD: It travels on a movable dovetailed scrapped slide and can be tilted from 0 to 3 degrees to obtain different feed rates for workpiece. Regulating wheel spindle is made of hardened and ground alloy steel. It runs in adjustable split bronze bearings lubricated by plunger pump. - WHEEL TRUING DEVICE: The grinding wheel and regulating wheel are equipped with separate truing devices, which are hydraulically operated, so that evenly smooth true wheels can be obtained for efficient cutting, uniform accuracy and better surface finish on the workpiece. The grinding wheel truing device is provided with a swiveling device arrangement. By fixing templates on grinding wheel truing device profiles can be obtained. The regulating wheel truing device is also provided with a swiveling arrangement. The truing units travel on a dovetailed slide, the movement of the unit can be controlled by a control valve knob. |

|

Specifications

|

| Standard Accessories: Grinding wheel, regulating wheel, two truing devices, single ended work rest blade, electric motors, coolant pump with tank, electric control panel, allen keys, spanners, set of wheel pullers and ‘V’ belts |

| Optional Accessories: Wheel balancing stand, wheel balancing arbor, additional wheel flanges for emery grinding wheel and regulating wheel, special work rest blades |

|

Maneklal Global Exports |

|

A NUESTRA PÁGINA DE MÁQUINAS HERRAMIENTAS |