|

|

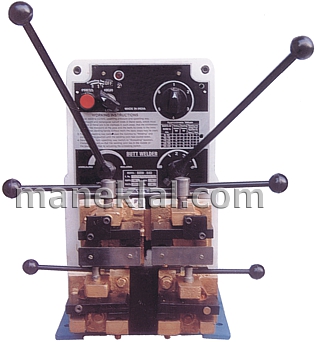

| Soldadoras a Tope Micro para Alambre Fino |

|

Proceso de Soldadura: - Los extremos de los alambres a soldar se 'preparan' por el accesorio para cortar / cizalla (accesorio opcional). - De acuerdo al diámetro de alambre a soldar, se ajustan la corriente de soldadura y la brecha. - Los extremos de los alambres se sujetan rígidamente mediante abrazaderas especiales de acción rápida. Para asegurar la correcta alineación de los extremos del alambre, se ven los alambres a través de una lupa (opcional). - Al pulsar el botón de soldar, el ciclo de soldadura a tope es iniciado y completado automáticamente por controles integrados. - Los alambres soldados se recocen en el dispositivo de recocido (opcional), si es necesario.

|

| Especificaciones: |

| Modelo: | MMBW-12 | MMBW-15 | MMBW-20 | MMBW-25 | MMBW-08C | MMBW-15C | MMBW-25C | MMBW-30C | MMBW-35C |

| Potencia Indicada (KVA): | 1 | 1 | 1 | 1 | 1 | 1 | 3 | 4 | 5 |

| Voltaje: | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 400 |

| Frecuencia (Hz): | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Fase: | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 |

| Potencia Indicada del Fusible: | 6 | 6 | 6 | 6 | 6 | 6 | 13 | 13 | 16 |

| Accesorio de cortar para alambre de diámetro (mm) | 0.3 - 1.2 | 0.5 - 1.5 | 0.7 - 2.0 | 0.7 - 2.5 | 0.3 - 0.8 | 0.5 - 1.5 | 0.8 - 2.5 | 0.8 - 2.5 | 1.5 - 3.8 |

| Dimensiones (mm): | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 213 x 193 x 450 | 220 x 200 x 450 | 240 x 300 x 450 |

| Peso Neto (kilos): | 15.5 | 15.5 | 15.5 | 15.5 | 15.5 | 15.5 | 20 | 20 | 35 |

| DATOS DE SOLDAR | |||||||||

| Materia a Soldar: | Hierro, Acero, Níquel | Hierro, Acero, Níquel | Hierro, Acero, Níquel | Hierro, Acero, Níquel | Cobre, Latón, Bronce, Aluminio | Cobre, Latón, Bronce, Aluminio | Cobre, Acero de Alto Carbono, Aluminio, Acero Suave | Hierro, Acero, Níquel Cobre, Latón, Aluminio, Acero de Alto Carbono | Hierro, Acero, Níquel Cobre, Latón, Aluminio, Acero de Alto Carbono |

| Capacidad de Soldar en Diámetro (mm): | 0.3 - 1.2 | 0.5 - 1.5 | 0.7 - 2.0 | 0.8 - 2.5 | 0.3 - 0.8 | 0.5 - 1.5 | 0.8 - 2.5 | 1.0 - 3.0 | 1.5 - 3.8 |

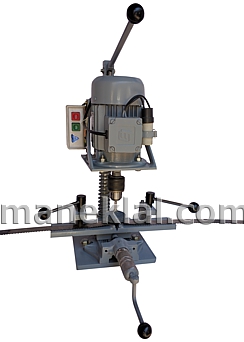

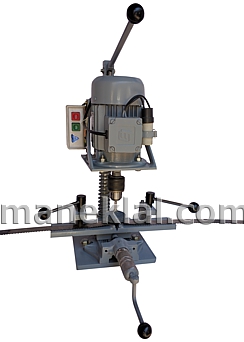

| Soldadoras a Tope para Alambre |

|

Proceso de Soldadura: - La operación de soldadura en estas máquinas es automática y los ajustes son fáciles - Separación de electrodos se ajusta mediante una palanca contra una placa calibrada para diámetro de alambre - Presión de recalcado se ajusta por medio de un cuadrante calibrado para diámetro de alambre. - La corriente de soldadura se selecciona mediante un interruptor giratorio - Los alambres a soldar deben ser cortadas rectas, exactamente en ángulo recto y libre de rebabas - Los extremos de alambre se sujetan por un dispositivo de sujeción con resorte que se puede abrir por separado o juntos por pedales - La liberación de los pedales deja el alambre sujeta a presión adecuada - Por pulsar el botón, el ciclo de soldadura se inicia y se completa automáticamente por controles integrados - Después de la soldadura, el alambre esta recocido, si es necesario, en los electrodos de recocido Presentaciones: |

|

|

Especificaciones: |

| Modelo: | MWBW-5 | MWBW-8 | MWBW-10 | MWBW-12 | MWBW-20 | |

| Potencia Indicada (KVA): | 5 | 8 | 10 | 12 | 20 | |

| Ciclo de Trabajo a Potencia Indicada Máx.: | 2% | 0.73% | 0.73% | 0.56% | 0.45% | |

| Voltaje: | 400 | 400 | 400 | 400 | 400 | |

| Frecuencia (Hz): | 50 | 50 | 50 | 50 | 50 | |

| Fase: | 1 | 1 | 1 | 1 | 1 | |

| Potencia Indicada del Fusible: | 10 | 10 | 10 | 15 | 15 | |

| Peso Neto con el Pedestal Móvil (kilos): | 57 | 64 | 64 | 64 | 64 | |

| Dimensiones con el Pedestal Móvil (mm): | 915 x 685 x 1120 | 915 x 685 x 1120 | 915 x 685 x 1120 | 915 x 685 x 1120 | 915 x 685 x 1120 | |

| DATOS DE SOLDAR | ||||||

| Materia a Soldar: | Hierro, Acero | Acero de Aleación y Acero al Carbono | Acero de Aleación y Acero al Carbono | Cobre y Latón | Acero de Aleación Ligeros | |

| Capacidad de Soldar - Diámetro de Alambre (mm): | Acero con Carbono menos que 0.5%, Acero sin Aleación | 2 - 8 | 2 - 8 | 2 - 10 | 1 - 5 | 3 - 8 |

| Acero con Carbono entre 0.5 y 1%, Acero de Aleación | -- | 2 - 8 | 2 - 8 | -- | -- | |

| Cobre | 2 - 3 | -- | -- | 1 - 4 | 2.5 - 6 | |

| Aluminio, Metal Ligero | 3 - 5 | -- | -- | 1.5 - 6 | 4 - 7 | |

|

|

|

|

|

|

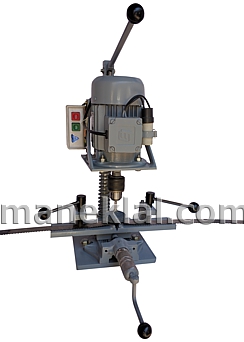

Modelo: MWBW-8 con Opcional: Rectificadora para quitar rebaba |

Modelo: MWBW-8 con Opcional: Rectificadora y Tornillo de Banco |

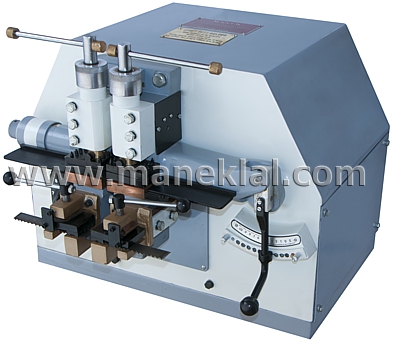

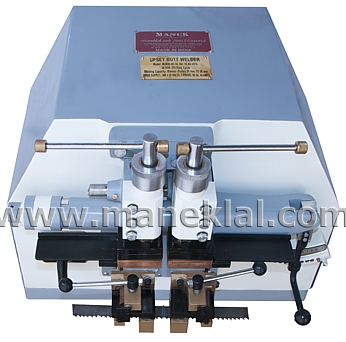

| Soldadoras a Tope con Recalcado |

|

|

Aplicación: - Para soldadura a tope con recalcado de todos perfiles de alambres y planchuelas de hierro, acero, aleación, acero al carbono, cobre, aluminio, latón y otros metales ligeros y sus aleaciones Presentaciones: |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

| Soldadoras a Tope para Barras / Alambrón y Sierras de Acero al Carbono y Bimetálico |

|

Aplicación: - Para soldadura a tope con recalcado de todos perfiles de alambres y planchuelas de hierro, acero, aleación, acero al carbono, cobre, aluminio, latón y otros metales ligeros y sus aleaciones Y también sierras de acero al carbono y sierras bimetálicas Usuarios: Presentaciones: |

|

Ajustes Sencillos: 1. SEPARACIÓN DE ELECTRODO: Ajuste con la palanca en la placa de indexación. 2. CORRIENTE DE SOLDADURA: Ajuste con interruptor giratorio de 8 posiciones. Corriente encendido y apagado automáticamente a por contactor electromagnético incorporado. 3. PRESIÓN DE RECALCADO: Regulable micrométricamente con mando de presión. 4. CORRIENTE ENCENDIDO / APAGADO: Regulable micrométricamente con dedal sencillo. Proceso de soldadura: Detalles Técnicos: |

|

|

| Especificaciones: |

| Modelo: | MRBW-15 | MRBW-20 | MRBW-25 | MRBW-30 | MRBW-40 | MRBW-50 | MRBW-60 | MRBW-75 | MRBW-100 | MRBW-150 |

| Potencia Indicada (KVA): | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | 150 |

| MATERIA A SOLDAR | ||||||||||

| Acero Suave (diámetro mm): | 3-12 | 4-14 | 5-16 | 6-17 | 8-18 | 10-20 | 16-22 | 18-25 | 19-28 | 20-31 |

| Acero de Alto Carbono (diámetro mm): | 3-9 | 4-11 | 5-12 | 6-13 | 7-14 | 8-15 | 10-16 | 12-17 | 12-18 | 13-20 |

| Cobre (diámetro mm): | 3-7 | 4-8 | 5-9 | 6-10 | 7-11 | 8-12 | 10-14 | 12-15 | 12-18 | 13-20 |

| Latón (diámetro mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Aluminio (diámetro mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Sierra de Acero al Carbono (ancho mm): | 20-40 | 30-50 | 30-60 | 35-75 | -- | -- | -- | -- | -- | -- |

| Sierra Bimetálica (ancho mm): | 5-27 | 20-37 | 25-41 | 30-45 | 35-50 | 35-60 | 40-65 | -- | -- | -- |

| Fusible (amperios): | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 180 | 250 | 375 |

| Ciclo de Trabajo: | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% |

| Dimensiones (mm): | 775 x 525 x 1050 | |||||||||

|

|

| Soldadoras a Tope para Barras / Alambrón - Operadas Neumáticamente con Temporizador Electrónico Tiristorizado |

|

Aplicación: - Para soldadura a tope con recalcado de todos perfiles de alambres y planchuelas de hierro, acero, aleación, acero al carbono, cobre, aluminio, latón y otros metales ligeros y sus aleaciones Y también sierras de acero al carbono y sierras bimetálicas Usuarios: Presentaciones: |

|

| Especificaciones: |

| Modelo: | MRBW-15P | MRBW-20P | MRBW-25P | MRBW-30P | MRBW-40P | MRBW-50P | MRBW-60P | MRBW-75P | MRBW-100P | MRBW-150P |

| Potencia Indicada (KVA): | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | 150 |

| MATERIA A SOLDAR | ||||||||||

| Acero Suave (diámetro mm): | 3-12 | 4-14 | 5-16 | 6-17 | 8-18 | 10-20 | 16-22 | 18-25 | 19-28 | 20-31 |

| Acero de Alto Carbono (diámetro mm): | 3-9 | 4-11 | 5-12 | 6-13 | 7-14 | 8-15 | 10-16 | 12-17 | 12-18 | 13-20 |

| Cobre (diámetro mm): | 3-7 | 4-8 | 5-9 | 6-10 | 7-11 | 8-12 | 10-14 | 12-15 | 12-18 | 13-20 |

| Latón (diámetro mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Aluminio (diámetro mm): | 4-9 | 5-10 | 6-11 | 7-12 | 8-13 | 8-14 | 10-16 | 12-17 | 13-19 | 14-22 |

| Sierra de Acero al Carbono (ancho mm): | 20-40 | 30-50 | 30-60 | 35-75 | -- | -- | -- | -- | -- | -- |

| Sierra Bimetálica (ancho mm): | 5-27 | 20-37 | 25-41 | 30-45 | 35-50 | 35-60 | 40-65 | -- | -- | -- |

| Fusible (amperios): | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 180 | 250 | 375 |

| Ciclo de Trabajo: | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% |

| Dimensiones (mm): | 900 x 800 x 1300 | 900 x 800 x 1300 | 950 x 850 x 1450 | 950 x 850 x 1450 | 1100 x 900 x 1500 | 1100 x 900 x 1500 | 1100 x 950 x 1500 | 1100 x 950 x 1500 | 1550 x 1050 x 1600 | 1550 x 1050 x 1600 |

| Volumen de Embarque (m3): | 1.0 | 1.0 | 1.2 | 1.1 | 1.5 | 1.5 | 1.6 | 1.6 | 2.6 | 2.6 |

|

|

|

|

|

| Soldadoras a Tope para Sierras de Cinta / Sierras Sin Fin |

|

Proceso de Soldadura:

Proceso para Recocer: |

Modelo: MBW-15B |

Modelo: MBW-18B (con accesorio optional: Aparato para Recocer Automaticamente) |

|

|

|

|

|

|

VIDEO DE LA MAQUINA SOLDADORA A TOPE PARA SIERRAS SIN FIN MODELO: MBW-18B con APARATO PARA RECOCER AUTOMATICO |

Modelo: MBW-3B (con accesorios opcionales para Cortar y Rectificar) |

Modelo: MBW-12B |

Modelo: MBW-15B |

Cortador Abrasivo independente |

Accesorios Opcionales:

1. Accesorio para Recocer Automaticamente (en

lugar de recocer manualmente) 2. Accesorio para Cortar: Para cortar las

sierras a 90o |

Rectificador independente |

| Soldadoras a Tope con Recalcado para Sierras de Cinta / Sierras Sin Fin |

|

Aplicación: - Para soldar Sierras de Cinta de Acero al Carbono y Bi-metálica Presentaciones: |

|

|

|

|

Especificaciones: |

| Modelo: | MUBW-20B | MUBW-25B | MUBW-30B | MUBW-40B | MUBW-50B | MUBW-60B |

| Capacidad Nominal (KVA): | 20 | 25 | 30 | 40 | 50 | 60 |

| MATERIA A SOLDAR | ||||||

| Ancho de Sierra sin Fin de Acero al Carbono (mm): | 30-60 | 30-65 | 35-75 | -- | -- | -- |

| Ancho de Sierra sin Fin Bi-metálica (mm): | 20-37 | 25-41 | 30-45 | 35-50 | 35-60 | 40-65 |

| Fusible (amperios): | 40 | 50 | 75 | 100 | 125 | 150 |

| Ciclo de Trabajo: | 10% | 10% | 10% | 10% | 10% | 10% |

| Dimensiones (mm): | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 | 775 x 525 x 1050 |

|

|

Cortador Abrasivo independente |

Accesorios Opcionales:

1. Cortador Abrasivo independente: Para

cortar las sierras a 90o |

Rectificador independente |

| Soldadoras a Tope con Arco - Operadas Neumáticamente - para Sierras de Cinta / Sierras Sin Fin |

|

Aplicación:

Operación Fácil: |

|

Proceso de Soldadura:

Proceso de Recocer: |

|

|

Especificaciones: |

| Modelo: | MFBW-30 | MFBW-40 |

| Capacidad Nominal (KVA): | 30 KVA | 40 KVA |

| CAPACIDAD DE SOLDAR: | ||

| Ancho de Sierra Bi-metálica: | 27 - 54 mm | 41 - 65 mm |

| Espesor de Sierra Bi-metálica: | 0.9 - 1.6 mm | 0.8 - 1.4 mm |

| Corriente de Entrada: | 75 Amps | 100 Amps |

| Ciclo de Trabajo: | 10% | 10% |

| Peso Neto / Bruto: | 150 / 250 kg | 150 / 250 kg |

| Dimensiones: | 1650 x 975 x 1500 mm | 1650 x 975 x 1500 mm |

|

|

Cortador Abrasivo independente |

Accesorios Opcionales:

1. Cortador Abrasivo independente: Para

cortar las sierras a 90o |

Rectificador independente |

| Sierras de Cinta |

|

- Rollos de Sierra de Cinta de Acero al Carbono para

cortar Madera, Plásticos y Aceros de Baja Aleación. - Rollos de Sierra de Cinta Bi-metálica para cortar Acero. |

|

|

Sierra de

Cinta de Acero al Carbono: |

| Ancho x Espesor |

Diente Estándar (TPI) Diente por Pulgada (por 25 mm) |

Diente tipo Gancho (TPI) Diente por Pulgada (por 25 mm) |

| 6.0 x 0.63 mm (1/4" x 0.025") | 10, 14, 18, 24 | 4, 6 |

| 10.0 x 0.63 mm (3/8" x 0.025") | 4, 6, 8, 10, 14, 18, 24 | 3, 4, 6 |

| 12.5 x 0.63 mm (1/2" x 0.025") | 6, 8, 10, 14, 18, 24 | 3, 4, 6 |

| 16.0 x 0.80 mm (5/8" x 0.032") | 6, 8, 10, 14, 18 | 3, 4, 6 |

| 20.0 x 0.80 mm (3/4" x 0.032") | 6, 8, 10, 14, 18 | 3, 4, 6 |

| 25.0 x 0.90 mm (1" x 0.035") | 4, 6, 8, 10, 14 | 2, 3, 4, 6 |

|

|

| Ancho x Espesor |

Diente Estándar (TPI) Diente por Pulgada (por 25 mm) |

Diente tipo Gancho (TPI) Diente por Pulgada (por 25 mm) |

| 6.0 x 0.63 mm (1/4" x 0.025") | 8, 10, 14, 18, 24 | 4, 6 |

| 10.0 x 0.63 mm (3/8" x 0.025") | 8, 10, 14, 18 | 3, 4, 6 |

| 12.5 x 0.63 mm (1/2" x 0.025") | 6, 8, 10, 14, 18, 24 | 3, 4, 6 |

| 16.0 x 0.80 mm (5/8" x 0.032") | 10, 14, 18 | 4 |

| 20.0 x 0.80 mm (3/4" x 0.032") | 6, 8, 10, 14, 18 | 3, 6 |

| 25.0 x 0.90 mm (1" x 0.035") | 6, 8, 10, 14 | 2, 3, 4 |

|

|

| Ancho x Espesor | (TPI) Diente por Pulgada Constante | (TPI) Diente por Pulgada Variable |

| 13 x 0.60 mm | 10, 14, 18, 24 | 8/12, 10/14 |

| 13 x 0.90 mm | 10, 14, 18, 24 | 6/10, 8/12, 10/14 |

| 20 x 0.90 mm | 6, 10, 14 | 4/6, 5/8, 6/10, 8/12, 10/14 |

| 27 x 0.90 mm | 6, 10, 14 | 4/6, 5/8, 6/10, 8/12, 10/14 |

| 34 x 1.10 mm | 4, 6, 8 | 3/4, 4/6, 6/10, 8/12, 5/8 |

| 41 x 1.30 mm | 4, 6 | 3/4, 4/6, 8/12, 5/8 |

|

|

| Ancho x Espesor | (TPI) Diente por Pulgada Constante | (TPI) Diente por Pulgada Variable |

| 27 x 0.90 mm | -- | 2/3, 3/4, 4/6 |

| 34 x 1.10 mm | -- | 2/3, 3/4, 4/6 |

| 41 x 1.30 mm | -- | 2/3, 3/4 |

| 54 x 1.60 mm | -- | 2/3 |

| 67 x 1.60 mm | -- | 1.4/2, 2/3, 3/4, 0.75/1.25, 0.75/1.10 |

| 80 x 1.60 mm | -- | 1.4/2, 2/3, 3/4, 0.75/1.25, 0.75/1.10 |

|

Maneklal Global Exports |

|

A NUESTRA PAGINA SOBRE MAQUINAS SOLDADORAS |